Custom Clothing Logo Tags — Metal Hang Tags, Labels & Nameplates

Custom clothing logo tags set the foundation for a memorable brand experience. Whether you’re launching a fashion label, expanding a bag line, or producing industrial uniforms, the right metal tag not only conveys your brand’s identity but also assures durability and quality that lasts beyond a first impression. Modern brands demand logo tags for clothing that combine aesthetics with function, creating enduring value from manufacturing to retail display.

Key Takeaways

- Custom logo tags elevate your brand’s presentation and perceived value.

- Material and finish choices impact durability and visual style.

- Choosing an experienced manufacturer like UC Tag ensures a seamless process and high-quality results.

Common Metal Logo Tag Types

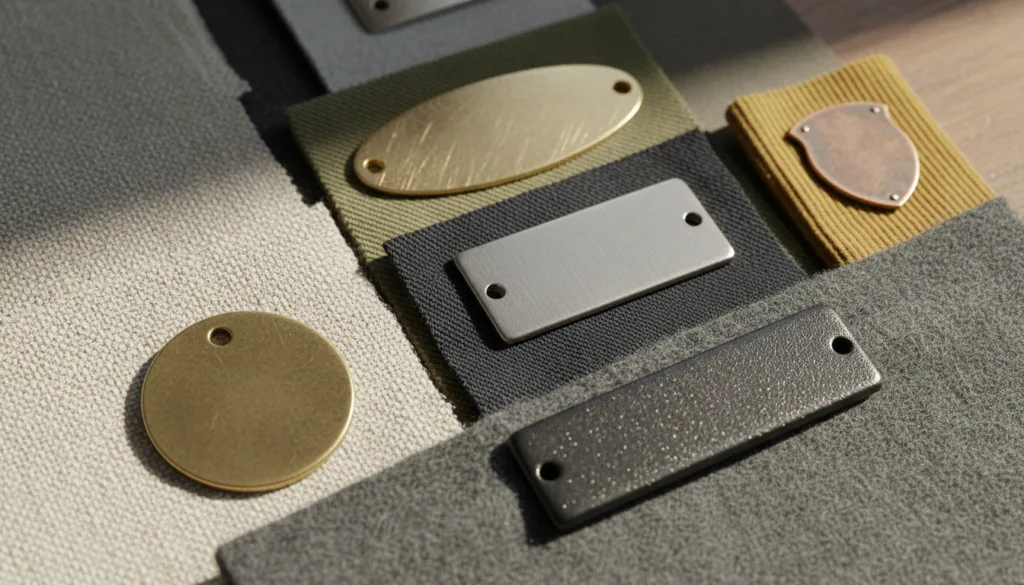

Today’s brands use a variety of metal logo tags for clothing to differentiate their apparel and accessories. The primary types include:

- Metal hang tags with logo — These detachable tags often hang from garments with cord or chain, ideal for product launches and premium retail lines.

- Sewn-in nameplates — Usually crafted from zinc alloy, brass, or stainless steel, these tags are stitched directly onto hems, sides, or pockets.

- Decorative plate labels — Flat or slightly domed metal pieces that attach via rivets or glue, widely used on bags and luggage.

- Fold-over logo tags — Tags bent in half, secured around garment edges for a modern look.

Material Comparison

| Material | Appearance | Weight | Best For | Cost |

|---|---|---|---|---|

| Zinc Alloy | Versatile finish options | Medium | Complex shapes, fine detail | $$ |

| Brass | Warm, yellowish hue | Medium | Vintage appeal, luxury | $$$ |

| Stainless Steel | Modern, glossy | Light | Simple designs, durability | $$ |

| Aluminum | Satin or brushed | Very light | Bags, lightweight apparel | $ |

Surface Finishes (Electroplating, Matte, Mirror, Antique Textures)

Custom logo tags for clothing can be finished in numerous ways to complement your brand’s style and product purpose. Professional manufacturers like UC Tag offer a full spectrum of finishes, applied during the final stages of production:

- Electroplating — A chemical process that coats the metal in a thin layer of nickel, chrome, brass, or other alloys. This technique provides high gloss, rust resistance, and a variety of color options.

- Matte/Brushed — A non-glossy finish is achieved by grit brushing or bead blasting, ideal for understated or industrial looks. Brushed finishes also resist fingerprints.

- Mirror Polish — Perfectly smooth and ultra-reflective, mirror polish is a statement finish favored by high-end brands.

- Antique Textures — Aging or “distressing” the tag with chemical baths or specialized plating methods results in vintage feels such as antique brass, copper, or silver tones.

Brand Logo Size & Position Standard

Logo clarity is essential for brand recognition. Industry best practices recommend sizing your logo to be legible at a glance but proportionate to the garment or accessory. Typical standards include:

- Hang tags: 20–40 mm length; clear zone 2 mm around logo

- Sewn-on plates: 15–30 mm width; positioned near visible seams

- Fold-over tags: 10–15 mm front face; positioned on edge

During manufacturing, high-resolution vector files (EPS, AI, CDR) are preferred. QC checks verify correct embossing/debossing depth and accurate placement according to your tech pack specifications.

Durability Tests

Durability is non-negotiable for clothing tags with logo. Testing validates that each tag’s finish and attachment will endure washing, friction, and environmental exposure. Core methods include:

- Salt Spray Test — Simulates years of corrosion exposure in just days (ASTM B117). Ensures coating resists tarnish on tags plated with gold, nickel, gunmetal, etc.

- Adhesion Test — Checks bonding strength and cohesion between plating/enamel and base metal; often involves crosshatch tape testing.

- Wear & Flex Test — Repeated rubbing or folding ensures nameplates won’t chip or delaminate on garments or bags.

- Laundry Simulation — Mimics washing cycles, especially for uniform or outdoor garment logo tags.

Reputable manufacturers like UC Tag routinely retain samples from each batch for post-production testing and reference, adhering to international quality standards.

Bulk Ordering Advantages + CTAs

Ordering metal hang tags with logo in bulk yields benefits extending far beyond per-unit cost. Strategic partners offer value-added services such as:

- Custom mold development for unique shapes & logos

- Color and finish consistency across large batches

- Pre-production samples and fast prototyping to validate design intent

- Streamlined logistics and variable packaging options (individually bagged, grouped sets, with/without eyelets/chain)

“Working with a specialized manufacturer like UC Tag guarantees you full control over your metal hang tag specs, finish quality, and lead time—an edge you need in today’s market.”

To unlock these benefits, always provide your design files and order requirements to your chosen supplier in advance. Ready to explore custom solutions? Contact UC Tag’s technical team for personalized support and fast sampling.

Designing Clothing Tags with Logo

The tag design process starts with your logo and product vision. Consider factors like tag shape, size, attachment style, and finish. Modern CAD/CAM tools and die-casting enable intricate detail—even small brands can access design-driven tags at reasonable MOQs. Partner with a skilled manufacturer for guidance on artwork file formats, tolerances, and testing protocols to guarantee your clothing tags with logo stand out from concept through mass production.

The Production Process for Logo Tags

The journey from concept to finished metal hang tag involves several technical steps. Each stage, when properly executed, ensures your logo displays with clarity and durability:

- Artwork proofing: Ensuring vector files, font outlines, and dimensions comply with tooling limits.

- Mold making: CNC/EDM machining forms hardened steel dies; tolerances typically ±0.05 mm.

- Die casting or stamping: Liquid metal (for zinc, aluminum) injected under pressure, or metal sheet stamped for brass/steel.

- Deburring & polishing: Removing sharp edges, smoothing surfaces for finishing.

- Surface finishing: Application of plating, brushing, antique baths, or enamel fill.

- Laser engraving or color fill: For sharp logos, Pantone-matched fills (if specified).

- QC inspection: Sampling per batch, visual checks under magnification, testing according to specifications.

- Packing & shipping: Bulk or individual packing options, with optional chain or cord attachment.

Benefits of Metal Hang Tags with Logo

Metal hang tags with logo instantly upgrade product presentation in retail and ecommerce settings. Among the measurable benefits:

- Boosted perceived product value and shelf appeal

- Clear, tactile branding for improved customer recall

- Long-lasting durability, surviving shipping, display, and even returns logistics

- Easy removal for post-purchase convenience

- Eco-friendly—many are recyclable or reusable, especially when securely attached with chain

Using custom metal tags can differentiate your brand from competitors relying on paper or woven labels, particularly for premium or limited-edition lines.

Attachment Methods for Logo Tags

Attaching logo tags for clothing requires selecting the right fixture to suit both style and durability needs. Popular methods include:

- Sew-on holes: Integrated during die-making, positioned for easy machine or hand-sewing.

- Rivets/eyelets: Secure, tamper-resistant option preferred for heavy canvas, denim, or bags.

- Iron-on adhesive backing: Used for branding where sewing isn’t possible or for fast application.

- Chains or cord: For removable hang tags, allowing for display without damaging the fabric.

Logo Tags for Clothing

Logo tags for clothing combine cutting-edge design and robust materials to ensure every garment makes a statement. Whether you’re after subtle elegance or eye-catching detail, these tags anchor your visual branding across collections. Always consider your product’s use case—workwear, kids’ apparel, or occasion fashion—to select the ideal finish, attachment, and durability.

Frequently Asked Questions

What is the minimum order quantity for custom clothing logo tags?

Most manufacturers offer low minimums, typically around 100–300 pieces per design for custom metal tags.

Which file formats are best for submitting my logo?

High-quality vector files (AI, EPS, or CDR) are ideal to ensure sharp detail and proper scaling in tag production.

How long does bulk production take after approval?

Production lead times are generally 2–4 weeks after sample approval, depending on order size and technical complexity.

Can I choose multiple finishes in one order?

Yes, reputable manufacturers can accommodate multiple finishes (e.g., antique gold, nickel, gunmetal) within the same order if required.

How are tags attached to clothing or bags securely?

Options include sewn-on holes, rivets, adhesive backing, or chains. Your manufacturer will advise on the best fit based on your product and design.

Are metal logo tags safe for children’s clothing?

With proper edge polishing, secure attachment, and non-toxic finishes, metal tags are suitable for kids’ garments. Always specify safety standards during ordering.