Introduction: The Dazzle of Rainbow Metal

Have you ever seen a metal surface shimmer with all the hues of the rainbow? That magical play of color isn’t a trick of the light—it’s a result of advanced surface treatment known as PVD coating. In this guide, we dive into Rainbow Metal: How PVD Coating Creates Iridescent Finishes. We’ll break down the science, showcase its uses, and reveal why PVD is transforming industries from high-end jewelry to cutting-edge automotive design.

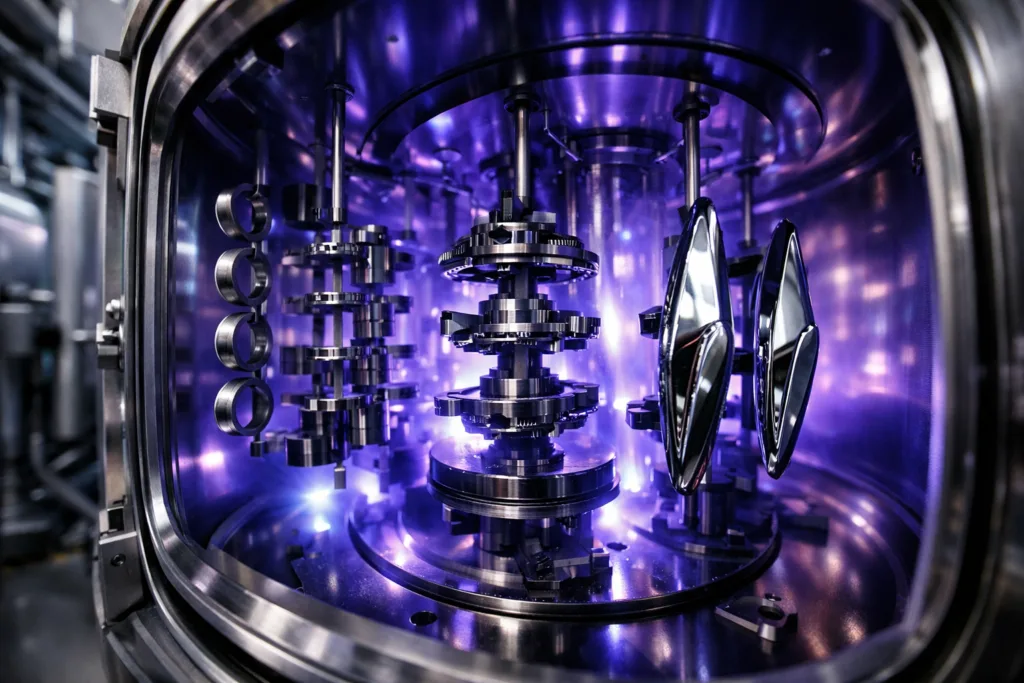

What Is PVD Coating? The Science Behind the Shine

PVD stands for Physical Vapor Deposition. It’s a process where metals like titanium or chromium are vaporized in a vacuum, then deposited atom by atom onto the surface of your base metal. This creates a thin, ultra-durable layer that can be engineered for different colors—including those stunning iridescent rainbow effects you see on some high-fashion tags, watches, or even car parts.

The Science of Iridescent Finishes

Iridescence means a surface changes color depending on how the light hits it. With PVD, this effect happens because light refracts and reflects off microscopic layers in the coating, much like the structure of butterfly wings or soap bubbles. The result is a spectrum of shifting colors that catch the eye and spark curiosity.

Types of Metals Suitable for PVD

While many metals can be coated, stainless steel, brass, copper, titanium, and zinc alloys are most common. Factors like base metal quality, desired thickness, and finish all impact the final effect. For applications like rainbow PVD dog tags, manufacturers select alloys that bond well with PVD layers and respond beautifully to iridescent treatment.

Comparing PVD to Traditional Plating Methods

Traditional electroplating uses chemical baths to apply metal finishes. PVD stands out by delivering:

- Superior hardness and scratch resistance

- Eco-friendly process with fewer toxic byproducts

- Long-lasting brilliance—no fading, tarnishing, or peeling

- Richer, more customizable color selection

| Feature | PVD Coating | Electroplating |

|---|---|---|

| Durability | High (abrasion & wear resistant) | Medium (can chip/flake long-term) |

| Color Options | Wide (rainbow, gold, black, etc.) | More limited |

| Eco Impact | Low (no hazardous waste) | Often high (chemical waste) |

| Finish Thickness | Very thin, precise | Thicker, less controlled |

How PVD Coating Creates Rainbow Effects

Certain metallic compounds, like titanium nitride, are used in the PVD process to create layers that refract light. By tweaking gas mixtures and deposition times, manufacturers “tune” the color effect—making a single piece shift from purple to green to gold as lighting changes. It’s a precise, repeatable method for making each item unique.

Industrial Applications of Iridescent Rainbow Metal

PVD-coated iridescent finishes aren’t just for looks—they increase resistance to corrosion and wear, extending product life in tough environments. Common applications include:

- Jewelry and fashion: For statement pieces and premium tags that catch the light.

- Automotive parts: Wheels, trims, gear levers—anything aiming for a tech-advanced look.

- Architectural hardware: Door handles, fixtures, panels, and decorative trims.

- Consumer electronics: Smartwatch bezels, phone buttons, and casing in limited editions.

Aesthetic Appeal: Why Designers Love Rainbow PVD

Designers choose PVD rainbow finishes because they’re visually striking, luxurious, and different from painted coatings. The color depth is richer, and the shifting effect turns an everyday item into a true conversation piece. Objects like custom logo tags or high polish mirror finishes become even more alluring with iridescence layered on top.

Functional Benefits: More Than Meets the Eye

Beneath the beauty, PVD-treated metals resist scratches, corrosion, and chemicals. This makes them perfect for tags and plates destined for outdoor use or high-contact areas. Maintenance is also easier—just a gentle wipe keeps colors vivid for years.

Customizability: Tuned Finishes for Every Project

PVD lets manufacturers match nearly any color scheme. By layering materials like titanium, zirconium, or chromium oxides, you can achieve blue, gold, green, purple, or full rainbow. Logos, texts, or QR codes can be etched before coating for total branding control. For example, UV printing on PVD surfaces unlocks even more vivid, multi-color possibilities.

Thickness and Surface Texture: Thin Yet Robust

PVD layers are typically 0.2–5 microns thick—microscopically thin but highly protective. Surface finish options range from glossy to matte. Combining techniques like sandblasting can add contrast between shimmering and soft-touch zones.

PVD in Jewelry: Rainbow That Endures

PVD coating is a revolution for jewelry makers. Compared to traditional plating, rainbow PVD jewelry doesn’t tarnish or discolor and is safer for sensitive skin, as it seals base metals away from direct contact. It’s the method of choice for contemporary rings, necklaces, and luxury branding tags seeking both endurance and visual drama.

PVD in Automotive and Industrial Design

Automotive trendsetters love rainbow finishes for custom wheels, interior highlights, and engine parts. It signals innovation and exclusivity. Similarly, industrial designers use PVD for hardware, tools, and components, combining vibrant style and surfaces that stand the test of time.

PVD in Architecture: Colorful Yet Practical

Building façades, elevator interiors, handrails, and light fixtures benefit from the corrosion-proof and colorfast nature of PVD coatings. Architects appreciate that iridescent surfaces do not require regular repainting or touch-up. A rainbow wall panel can last decades in any climate.

Environmental Impact: Is PVD Green?

PVD’s main environmental advantage is the absence of hazardous byproducts. Conventional plating methods can rely on toxic chemicals, which are difficult to recycle and often require costly disposal. PVD uses a vacuum and generates minimal waste, making it a strong choice for sustainable design practices.

PVD vs. Anodizing for Colorful Metals

Anodizing is another way to color metals like aluminum, but has limits on color variety and durability. In contrast, PVD provides bolder hues, longer wear, and works on a wider range of metals. Anodized finishes suit lightweight, low-wear applications; PVD is preferred where long-term color and scratch resistance matter.

Understanding the Cost of PVD Coating

PVD does cost more initially than basic chemical plating, but the reduced need for touch-ups, higher durability, and eco benefits often offset this over a product’s lifetime. Factors affecting price include batch size, finish complexity, and the base material.

Key Manufacturing Considerations

From a shop-floor point of view, achieving flawless rainbow PVD means paying attention to base metal prep, part geometry, and cleanliness before vacuum deposition. As Rain Chen at UC Tag notes, burr-free edges and surface smoothness are critical—the coating will mirror any underlying defects, so prep work is everything.

PVD Rainbow Metal and Brand Identity

Brands that want to stand out—including luxury luggage, pet products and tech gear—turn to rainbow PVD to signal innovation and visual appeal. The finish offers instant shelf presence and a sense of crafted rarity even for everyday goods. For special editions or limited-run tags, a rainbow effect can create a collector’s item with functional staying power.

Maintenance and Cleaning: Keeping the Colors Bright

Iridescent PVD finishes are low maintenance. Use a soft cloth or mild soap solution—avoid harsh abrasives. The ultra-hard surface resists fingerprints, water spots, and most chemicals, remaining vibrant for many years with little effort.

Common Problems and Solutions

Potential issues like pinholes or uneven color usually come from poor preparation or contamination. A manufacturer’s experience with sequencing washes, drying, and cleanroom controls is vital to avoid rejects. For intricate pieces, careful masking is used to produce defined multi-zone effects, as in dual plating applications or cut-out designs.

UC Tag Tips: Selecting Metal, Thickness, and Finish for PVD

Choosing metals like stainless steel or titanium assures an ideal bond, especially for items needing extra hardness or corrosion resistance. On smaller pieces, a thickness of 0.5–1 mm can make a tag feel premium but not overly heavy. For a subtle shimmer vs. bold rainbow, work with your fabricator to test small samples—color can shift slightly due to part size or geometry, as shop-floor experience shows.

PVD Rainbow Metal: How PVD Coating Creates Iridescent Finishes.

PVD-coated rainbow metals combine durability with show-stopping aesthetic appeal, making them the finish of choice for those who want to make a bold, lasting statement. Whether you’re manufacturing bespoke jewelry, high-end tags, or industrial hardware, PVD unlocks a palette of iridescent possibilities that’s hard to match any other way.

Conclusion

PVD coating delivers more than color—it adds protection, longevity, and visual intrigue to metal surfaces across industries. Rainbow PVD finishes set new standards for durability and customizable beauty in jewelry, automotive, architecture, and beyond. As more designers and brands recognize the value of this technology, rainbow metals are poised to become a signature look for the next generation of products.

Frequently Asked Questions

What metals are best suited for rainbow PVD coating?

Stainless steel and titanium are excellent choices due to their ability to form strong bonds with PVD layers and maintain vibrant, durable colors.

Does PVD rainbow finish scratch or fade easily?

No, PVD coatings are extremely hard and resistant to wear, making them much less likely to scratch or fade compared to paint or traditional plating.

Can I customize the iridescent color effect on my product?

Yes, manufacturers can adjust the PVD process to create specific ranges of color, including full-spectrum rainbow or single-color highlights.

How does PVD compare with anodizing for decorative metals?

PVD delivers a broader color range, more durability, and works with more metals than anodizing, which is mostly for aluminum.

Is PVD coating environmentally friendly?

Yes, PVD uses minimal chemicals and produces little waste, making it a greener alternative to traditional metal plating techniques.

What care is needed for rainbow PVD finishes?

Simply clean with a soft cloth and mild soap—no special polishes or harsh chemicals are required to keep the finish looking bright.

Related Reading

- Unlock Metallic Artistry: Dual Plating Secrets for Multi-Color Metal Tags

- Mirror Finishes Unveiled: Your Guide to Luxury-Grade Metal Tags

- Vivid Customization: How UV Printing Reinvents Metal Color Options

- Matte Meets Shine: Design with Sandblasted Metal Tags

- Rose Gold Impact: Stylish Metal Plating for Jewelry & Weddings

- Black Metal Revealed: Comparing Black Nickel & Dye for Modern Finishes